[October 4, 2023 – Taipei, Taiwan]

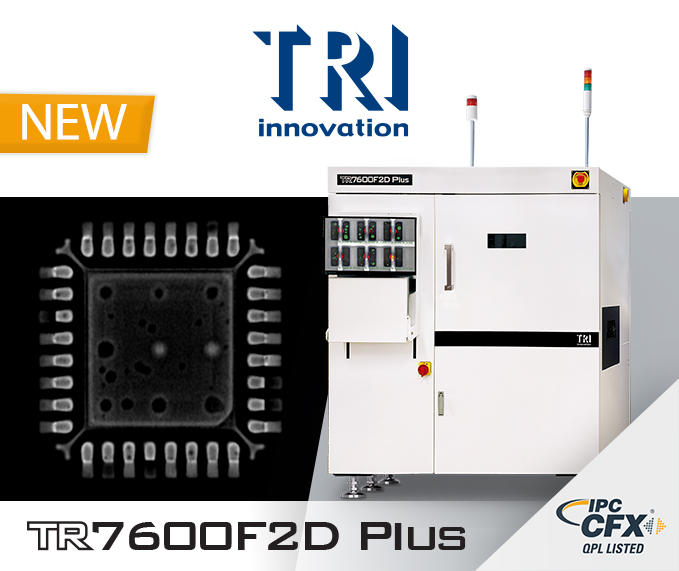

[October 4, 2023 – Taipei, Taiwan] Test Research, Inc. (TRI) proudly presents its latest breakthrough in X-ray Inspection, the TR7600F2D Plus. The TR7600F2D Plus is built on a new mechanical platform, delivering faster cycle times and a remarkable 10% performance boost compared to its predecessor. With a high-resolution range of 5 – 30 µm, it provides extensive inspection coverage, making it the preferred choice for multiple electronics manufacturing.

The system also accommodates large boards up to 900 mm x 460 mm. One of its remarkable features is its capacity to reliably detect defects in various components, including BGAs, Capacitors, Chips, WLCSP, DIMM Connectors, Flip-Chips, Ground Pads, Gullwing, Heat sinks, J-Leads, LED Chips, LGAs, Paladin Connector, Resistor, RNET, SiP, SMT Connectors, SOIC, SOT, Thermal Pad, QFNs, QFP, and THTs.

The TR7600F2D Plus has a 2D camera that simplifies adjustments, reduces calibration needs, and supports barcode reading, which is crucial for automotive industry applications. Its versatility makes it indispensable for manufacturers seeking top-tier quality assurance.

The TR7600F2D Plus seamlessly integrates with Smart Factory production lines and the MES of your choice, ensuring compatibility and future-proofing your production processes. The newly released AXI supports current Smart Factory Standards, including the IPC-CFX, IPC-DPMX, and The Hermes Standard (IPC-HERMES-9852).

For more information about the TR7600F2D Plus, please visit,

https://www.tri.com.tw/en/product/product_detail-12-2-1760-1.html

###

About TRI

Test Research, Inc. (TRI) provides the most cost-effective solutions to meet a comprehensive range of manufacturing test and inspection requirements, from Automatic Test and Inspection solutions to Board Testing. Learn more at

http://www.tri.com.tw. For sales and service information, please write to us at

marketing@tri.com.tw or call +886-2-2832 8918.