|

|

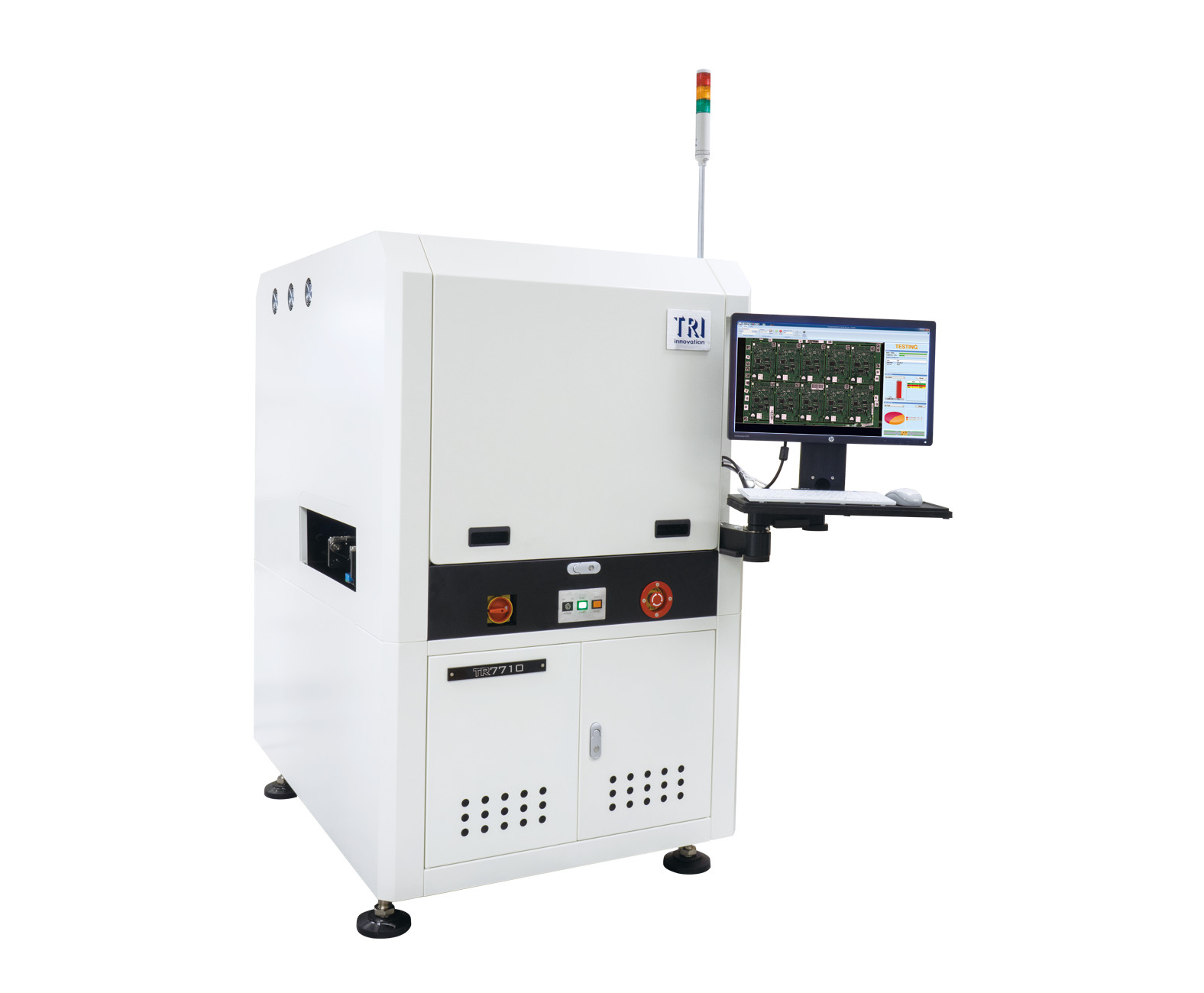

Inspección óptica automatizada (AOI)

|

TR7710

|

|

|

|

TR7710

|

|

|

INTRODUCTION

La plataforma AOI económica y customizable TR7710 combina un sistema de cámara de alta resolución e iluminación multi-fase exclusiva de TRI. La solución óptica ofrece un mayor rango de DOF para componentes altos. El software de inspección TRI Serie III combina un amplio rango de detección de defectos y una programación sencilla e inteligente, basada en CAD. La plataforma TR7710 esta diseñada para adaptarse a cualquier presupuesto sin comprometer la calidad de su linea de producción.

• Solución AOI en línea, económica y altamente personalizable

• Cámara a color de alta velocidad de 6,5 megapíxeles

• Asistente de interfaz de programación fácil optimizado para NPI

• Inspección Stop-and-Go con gran profundidad de campo (DOF)

• Resolución óptica de 10 µm o 12,5 µm

Optical System

| Imaging Method |

|

| Camera |

|

| Imaging Resolution |

|

| Lighting |

|

| 3D Technology |

|

| Field of View |

|

Inspection Performance

| Imaging Speed |

|

| Height Resolution |

|

| Max. Solder Height |

|

Motion Table & Control

| X-Axis Control |

|

| Y-Axis Control |

|

| Z-Axis Control |

|

| X-Y Axis Resolution |

|

| Z-Axis Resolution |

|

Board Handling

| Max PCB Size |

|

| PCB Thickness |

|

| Max PCB Weight |

|

| Top Clearance |

|

| Bottom Clearance |

|

| Edge Clearance |

|

| Conveyor Height |

|

Optical System

| Imaging Method |

Stop-and-Go |

| Top Camera |

6.5 Mpix |

| Angle Camera |

N/A |

| Imaging Resolution |

10 µm, 12.5 µm (factory setting) |

| Lighting |

Multi-phase RGB+W LED |

| 3D Technology |

N/A |

| Max. 3D Range |

N/A |

Inspection Performance

| Imaging Speed |

6.5 Mpix@ 10 µm: 27 cm²/sec

6.5 Mpix@ 12.5 µm: 42 cm²/sec

|

Motion Table & Control

| X-Axis Control |

Ballscrew + AC-servo controller |

| Y-Axis Control |

Ballscrew + AC-servo controller |

| Z-Axis Control |

N/A |

| X-Y Axis Resolution |

1 µm |

Board Handling

| Max PCB Size |

TR7710@ 10 µm, 15 µm: 510 x 460 mm

TR7710 DL@ 10 µm, 12.5 µm: 510 x 310 mm x 2 lanes, 510 x 590 mm x 1 lane |

| PCB Thickness |

0.6-5 mm |

| Max PCB Weight |

3 kg |

| Top Clearance |

25 mm |

| Bottom Clearance |

40 mm [100 mm optional] |

| Edge Clearance |

3 mm [5 mm optional] |

| Conveyor |

Inline

Height: 880 – 920 mm

* SMEMA Compatible

|

Inspection Functions

| Component |

Missing

Tombstoning

Billboarding

Polarity

Rotation

Shift

Wrong Marking (OCV)

Defective

Upside Down

Extra Component

Foreign Material

|

| Solder |

Excess Solder

Insufficient Solder

Bridging

Through-hole Pins

Lifted Lead

Golden Finger

Scratch/Contamination

|

Dimensions

| WxDxH |

TR7710: 1000 x 1400 x 1650 mm

TR7710 DL: 1000 x 1500 x 1650 mm

Note: not including signal tower, signal tower height 520 mm

|

| Weight |

TR7710: 600 kg

TR7710 DL: 650 kg

|

Imaging System

| Camera |

|

| X-ray Source |

|

| Imaging Resolution |

|

| Inspection Method |

|

Motion Table & Control

| X-Axis Control |

|

| Y-Axis Control |

|

| Z-Axis Control |

|

| X-Y Axis Resolution |

|

Board Handling

| Max PCB Size |

|

| PCB Thickness |

|

| Max PCB Weight |

|

| Top Clearance |

|

| Bottom Clearance |

|

| Edge Clearance |

|

| Conveyor Height |

|

Dimensions

| WxDxH |

|

| Weight |

|

| Power Requirement |

|

|