After careful selection process, were consolidated partnerships with worldwide reputation equipment manufacturers for structuring the main manufacturing processes of LABelectron.

Advanced research in assembly, welding and inspection of electronic boards, events and technical seminars for the promotion and dissemination of technologies developed in LABelectron and in their partners, make use of the laboratory environment of the factory showroom for LABelectron technology. These are just some points to be developed from the technology cooperation agreements that, throughout the month of July 2010, were signed with three major manufacturers of world class equipment for the electronics manufacturing process.

................................................................................................................................................................................................................

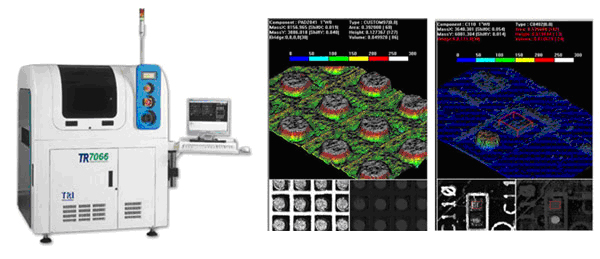

Automatic Inspection Equipment from Taiwan's TRI

The selection of Solder Paste Inspection Equipment (SPI) and Automatic Optical Inspection (AOI) was considered the most difficult, due to high technical qualifications of the vendors evaluated.

Considering technical aspects, of the partnership with the representative Teknosip / ETS (www.teknosip.com) as well as the integration of the inspection systems throughout the process, were selected four TRI equipments for the LABelectron automated inspection processes.

For solder paste inspection, were selected two units of the TRI model TR7066, shown in Figure 08. One Equipment will be installed in the NPI cell and the other one on the small series production line.

|

|

Figure 08 - SPI TRI TR7066 Equipment |

For optical inspection after reflow were selected two units of model TRI TR7500, showed in Figure 09.

|

|

Figure 09 - AOI TRI TR7500Equipment

|

During the next editions of LABelectron News, will be presented in greater detail the technical characteristics of equipment, as well as potential new support companies in the LABelectron, from new concepts of process and quality that are just being put into practice.

For more information about the LABelectron and his new model of performance and attendance, please contact us.

Eng Fadul Carlos Alberto Alves Correa - Director of LABelectron (cac@certi.org.br or 48-3239-2125)

http://www.labelectron.org.br/mostraNoticia.php?edicao=2010/julho¬icia=1